You may be very curious about how the shape of the beauty sponge is made.

This time I finally sorted out the complete production process of the beauty sponge, which is amazing!

The material of the beauty egg is neither latex nor our common sponge, but polyurethane.

1.grouting

In the feed pipe is a slurry of hydrophilic polyurethane raw materials, and the amount injected into the plastic mold is manually controlled by the worker.

Don't look at the way it is injected with only a small cup bottom, and then there is a foaming process, which will make the polyurethane material fill the entire cup. Look at the mold on the assembly line in the picture below, the raw materials that come out one by one are the finalized raw materials.

2.Grinding process

soft material

Use the beauty egg automatic grinding machine to make a rough shape! Everyone pay attention, the ground is some powder debris. Because the material of polyurethane is relatively loose and soft, it cannot be directly hit by a cutting knife like metal or wood, so it is actually a grinding method, which scrapes off scraps little by little.

The gourd-shaped makeup egg below is also symmetrical in the center.

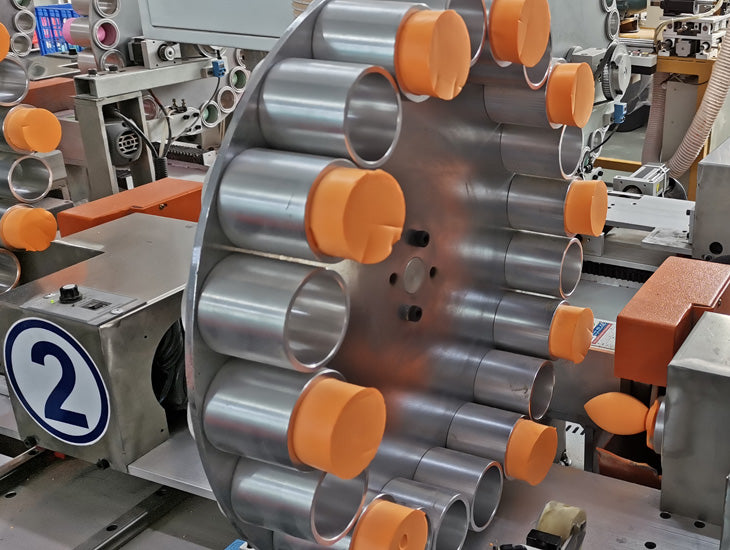

Let's change the angle and remove the shell of the grinding machine, and we can see clearly that there is actually such a grinding disc inside.

Miter cut beauty sponge

As for the most common beveled beauty sponge, the production process is simpler than I imagined...Put the finished centrally symmetrical beauty sponge into the mold fixed on the slide rail, snap it up and down, and then use Pushing your hand like this, you want a beveled makeup sponge, and the excess scraps are cut off... It is said that such a bevel is convenient for applying makeup to the corners of the face, such as the nose...

3.Manual quality inspection

The workers sit in rows and watch the process carefully. They need to carefully inspect the quality of each beauty egg before leaving the factory.

4.Cleaning process

Only beauty sponges that pass the quality inspection are eligible to enter our washing machine batch cleaning process, washing it is dizzying...

5.drying process

The drying tunnel in the picture below is very familiar to everyone~ It’s just that for the polyurethane material of the beauty sponge, it uses a combination of low temperature + hot air to dry~ (I found a moving picture of a cotton pad, the shape different but same machine!)

6.packing

Finally, after being sent to individual packaging, it is the most common beauty egg on hand